Posts Tagged: Arduino

Laser Engraver

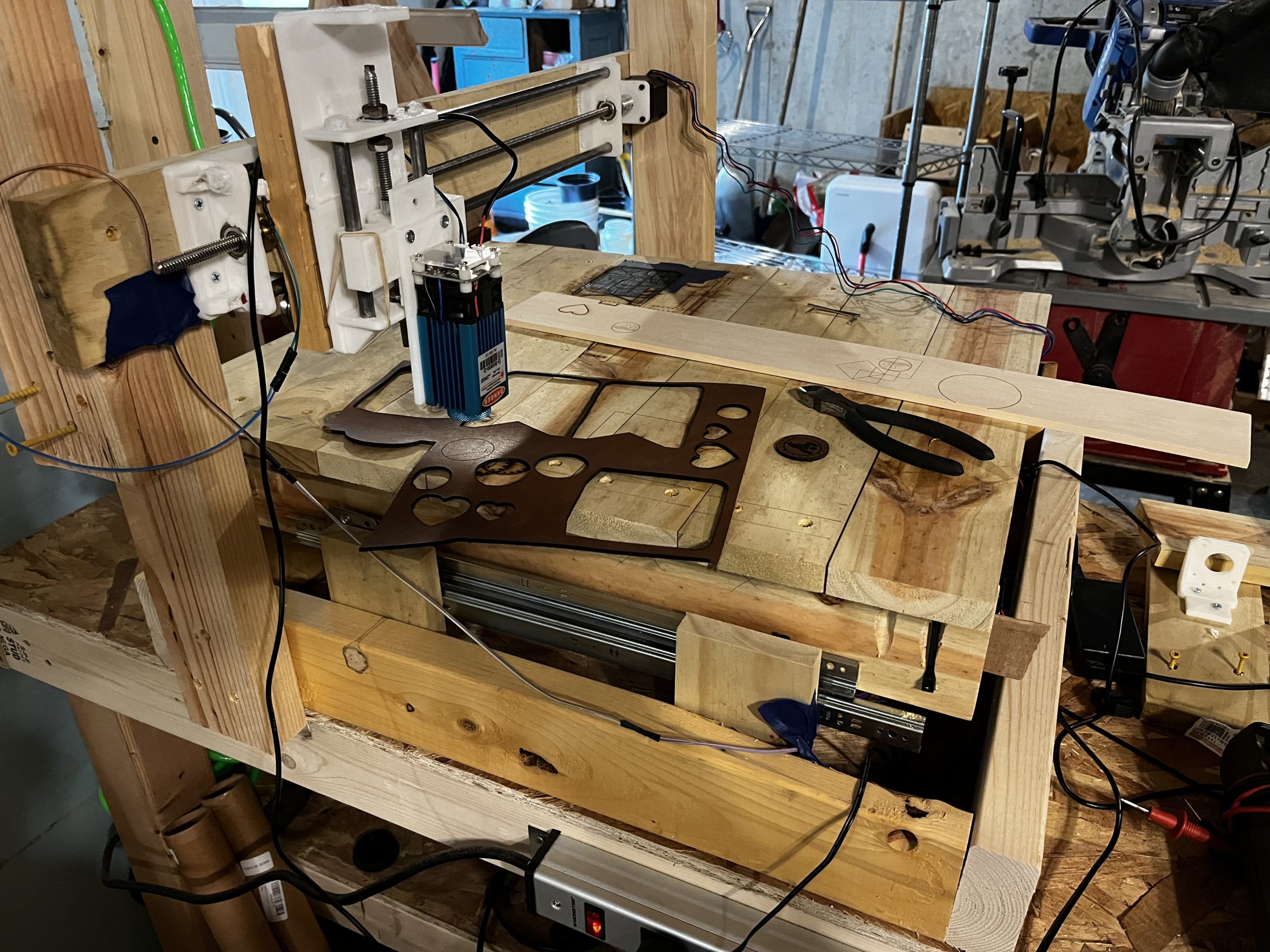

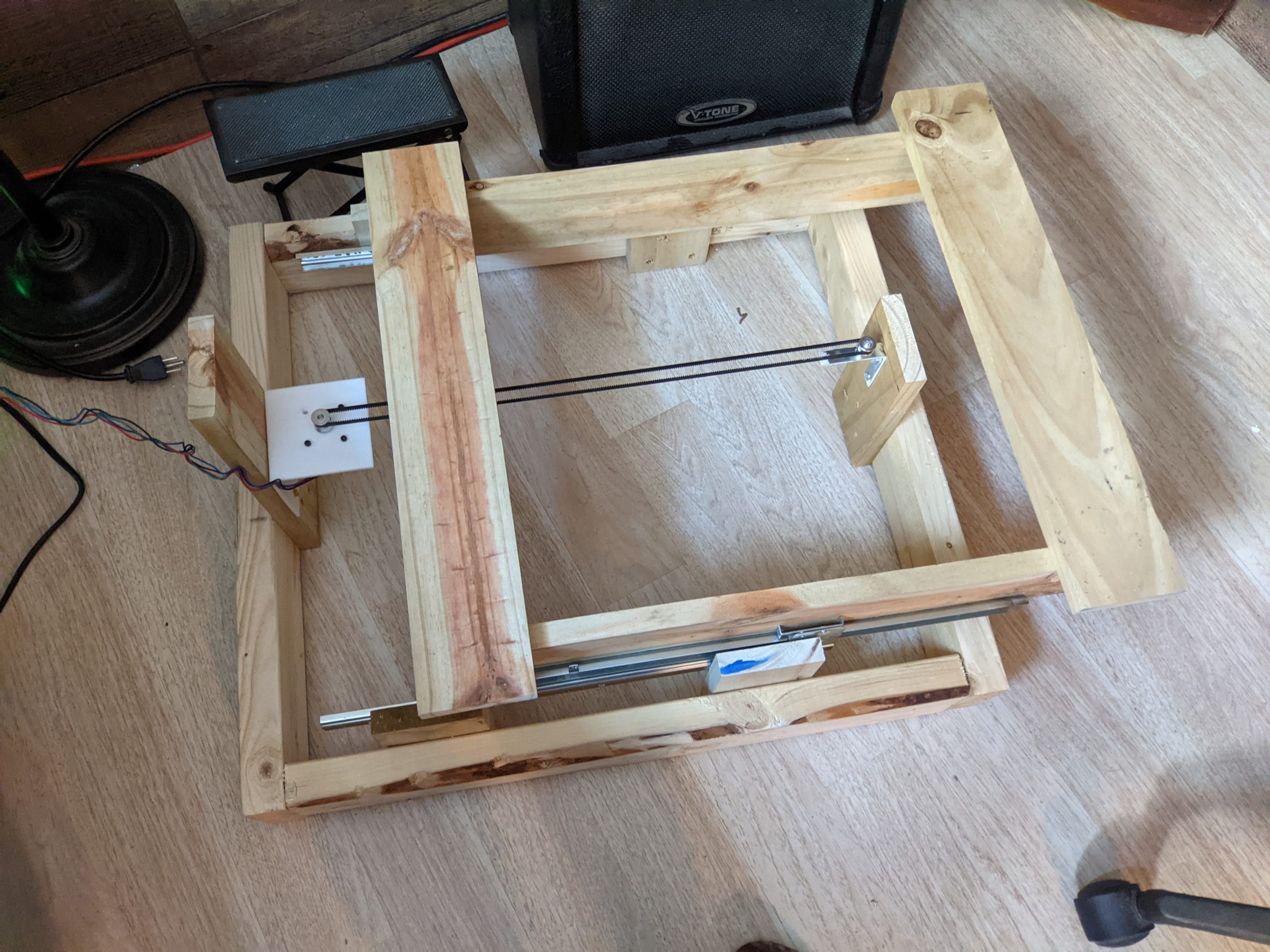

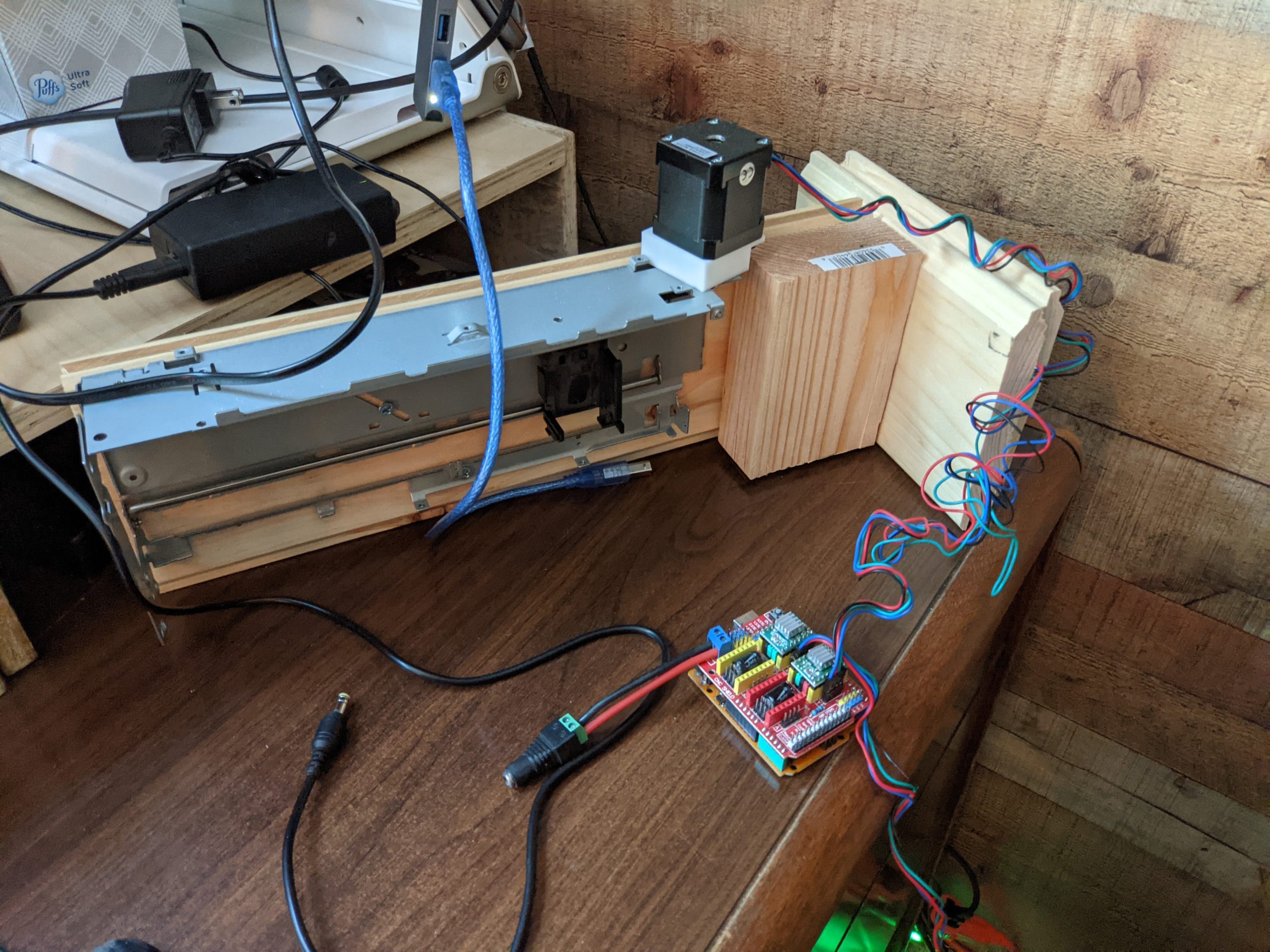

So I originally started with some old printer parts and had a small working laser engraver. I am using some drawer rails as the X axis and now I’ve got some 3/8 rods for the Y axis. I happen to have the v-slotted bearings that a friend gave me a while ago which work great as the carriage.

I ended up purchasing 4 of the precision threaded rods as the regular threaded rods you buy at the hardware store have a bit of a dead zone to them (found that out the hard way). I originally had my X axis using a single belt…then went to two motors with 2 belts…and finally swapped them over to using the precision rods. Now it is pretty solid, especially for using drawer rails to hold it together. =)

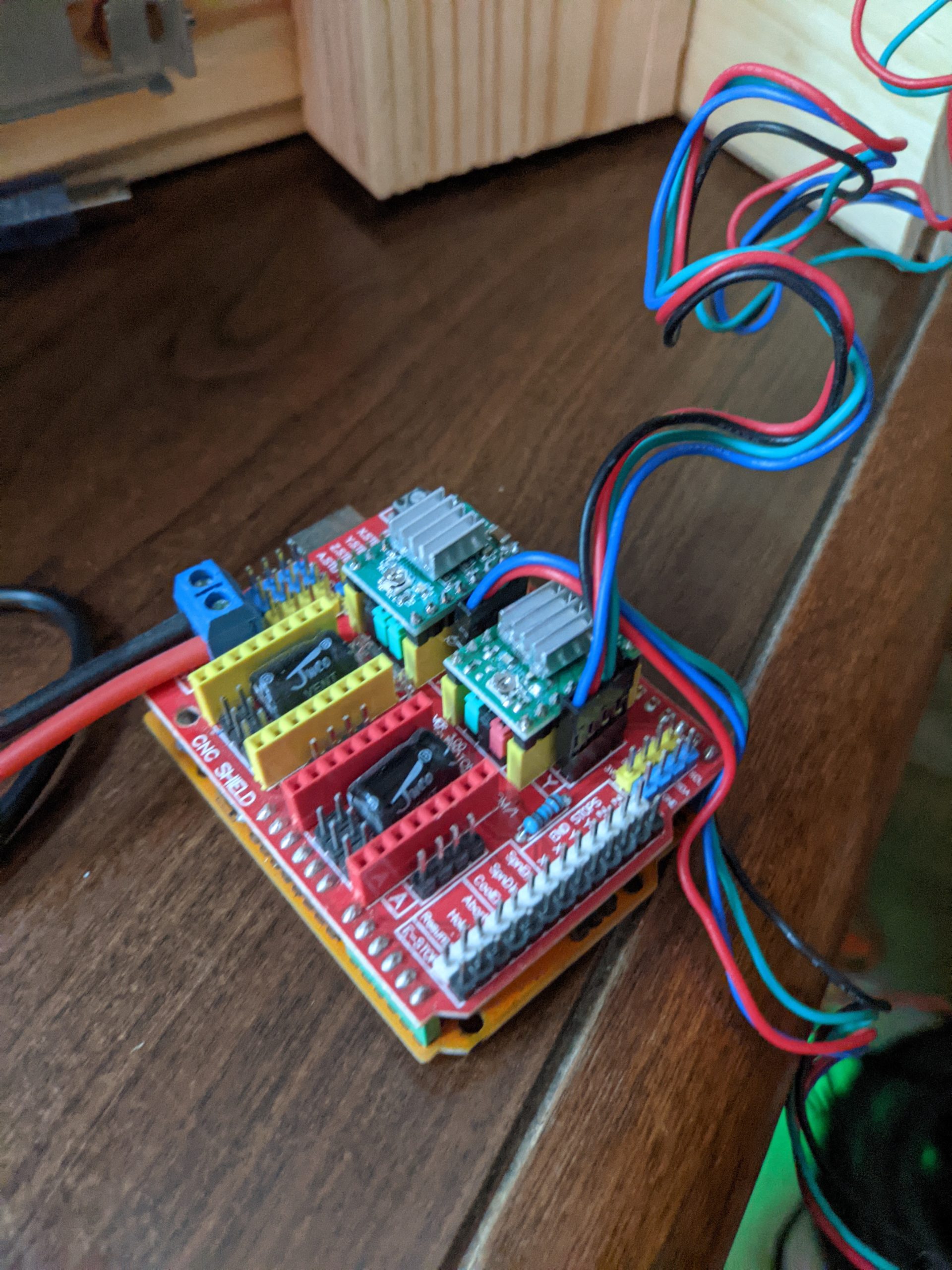

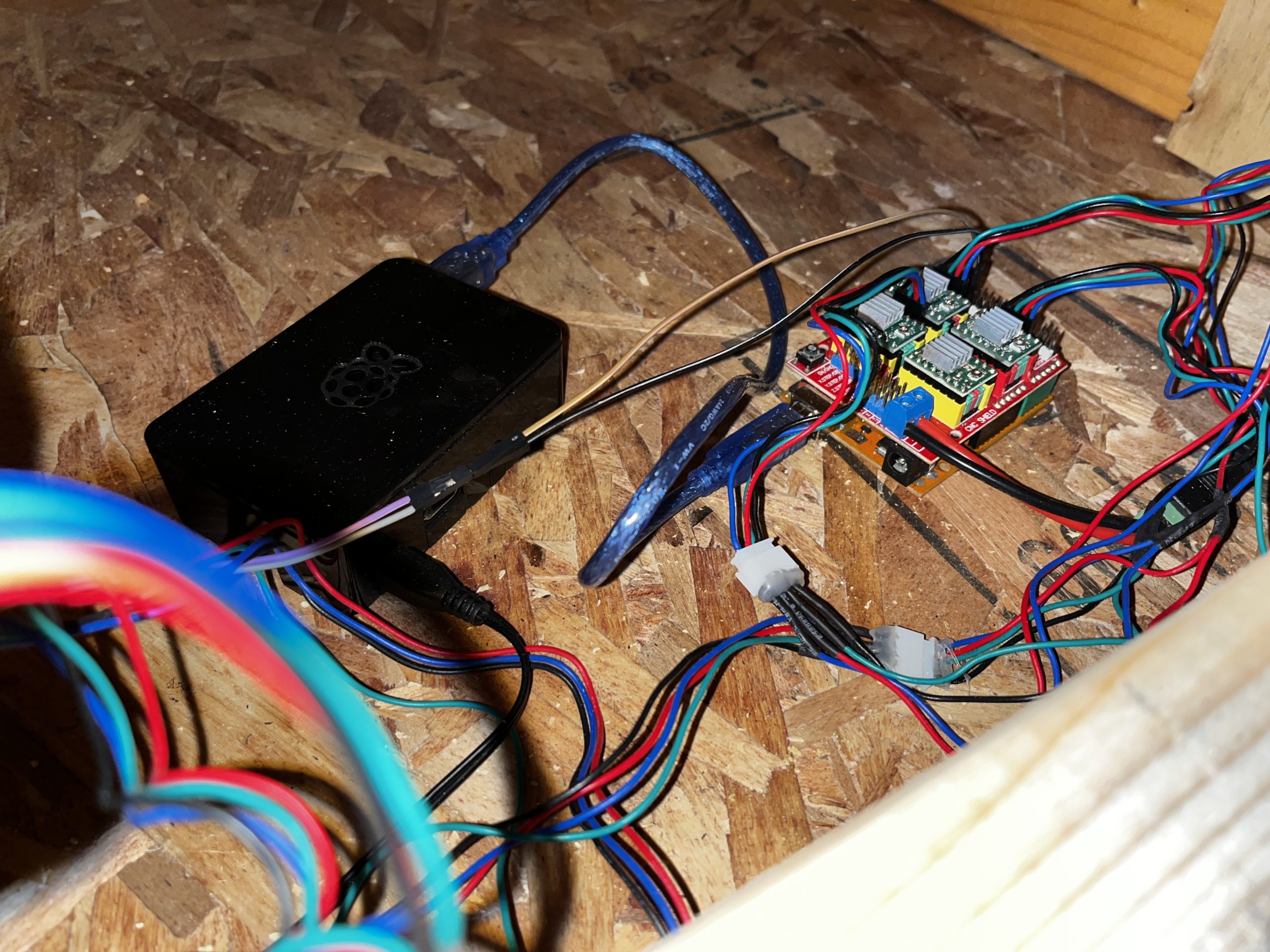

It’s all run by a raspberry pi running OctoPi and then an arduino uno with the cnc hat.

I originally had my Y axis using two 3/8 rods with a 3d printed carriage that slid onto the rods…but this proved too stiff and the laser would show a slight warping when the Y axis would change directions. I then swapped it to the v-slotted bearings and a wooded rig as the carriage. This slid much easier and required no real torque from the motor at all to move around.

My next step with this is to rig the carriage to hold my dremel and act as a sort of mini-cnc…and ultimately handle doing circuit boards!

Modified Power Wheels

Backstory

Back in 2016, we were about to bring home our new daughter from India. She has been diagnosed with Caudal Regression Syndrome. In her case, she is actually missing her legs. So when we saw that Power Wheels was about to release their new “Wild Thing” model, we thought it would be great for her to be able to play in the yard with the kids. Of course, the price wasn’t great at the time and we ended up forgetting about it.